Building an RV

Construction Skills

Many prospective builders are understandably anxious about the skills involved in constructing an airplane. The fact is that most RVs are built by people who have never built an airplane before. Many have never built anything before. Building an RV does not require any special skill, but it does demand attention, commitment and perseverance.

We make it as easy as we can, beginning with an aluminum airframe. The vast majority of airplanes built in the last 70 years have been constructed of aluminum. There are good reasons for this: it is light, strong, very adaptable and inexpensive. It does not require a controlled climate, does not need toxic adhesives and causes no health problems other than an occasional case of being “sick and tired” of working with it. Best of all, aluminum airplanes are quite easy to assemble, using skills that can be learned in less than an hour. (Riveting seems to worry prospective builders, probably because it is not a usual home shop skill like woodworking or welding. When you consider the history of aircraft construction it becomes less intimidating. In World War II, America suddenly needed thousands of sturdy airplanes. There was no time to train skilled workers, so the industry developed a method that allowed workers with absolutely no mechanical background to assemble airplanes at rates that have never been equaled. That method turned out to be riveted aluminum. Riveting was a skill that virtually anyone could learn their first day on the job.)

RV kits are very complete. All necessary aluminum forming is done; all welding is completed at the factory. Molded canopies and fiberglass parts are supplied. All the hardware is included. Most steel parts are powder coated. In RV-7/8/9/10/12/14 kits, rivet and bolt holes are pre-punched into all the parts. It is hard to overstate just how much labor and difficulty matched-hole pre-punching saves. All part alignments, fastener spacing’s and measurements are set at the factory. When the builder aligns the holes, the parts must be in the correct position.

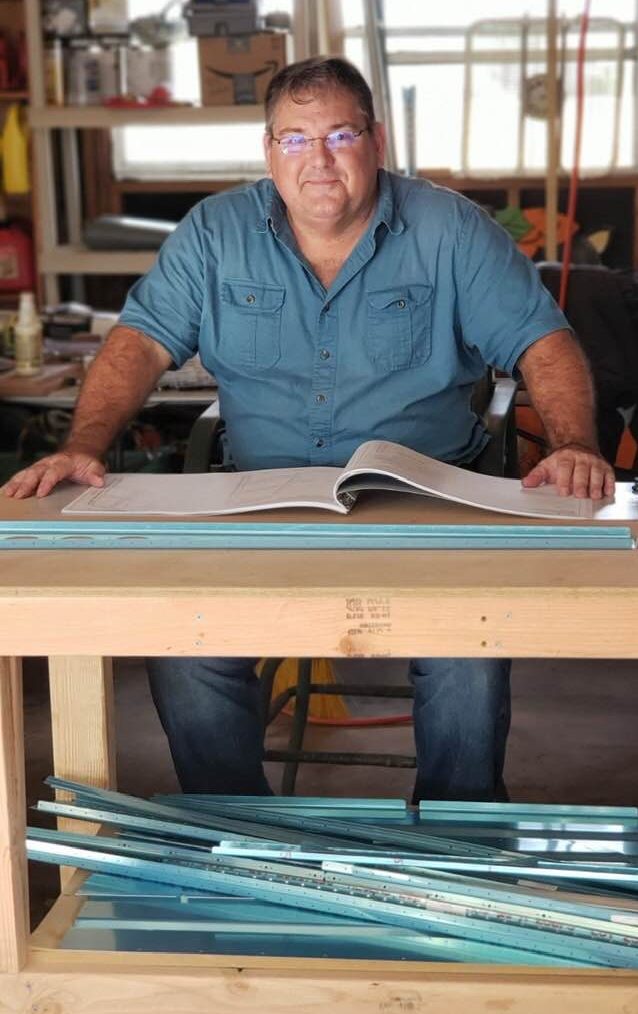

Tools / Construction Space

While there is no such thing as too big a shop, most RVs are built in the equivalent of a two-car garage. Many have been built in smaller spaces…some of them in much smaller spaces. The quality of the space is at least as important as the size of the space. Good light, air conditioning or heat as the climate requires, good ventilation and good organization are essential. An uncomfortable place to work means hurried, often poor, work.

This space should be as close to home as possible. A hangar at the airport might seem logical, but that’s often not the case. They rarely have climate control, sufficient electrical power or enough light to work in the evening. Even a short drive to work on the airplane can increase building time significantly. Still, even a distant shop is better than no shop, and organization and determination can overcome almost any obstacle.

Time to Build

How much time will it take an RV? That’s probably our hardest question to answer accurately. There are so many factors that affect building time that almost any answer will only be true for a small number of builders.

An RV-14 standard kit should take 1100-1200 hours. The Light Sport RV-12 takes only 800 hours until it’s ready to fly. The larger RV-10 might take 2000. As a rough approximation, based on builder reports we estimate about 2000-2200 “person-hours” for an RV-3 or RV-4, but significantly less time is involved in the matched-hole kits used to construct subsequent designs. Our estimate for the RV-7/8/9 airplanes is about 1400-1500 hours. These estimates presuppose a basic airplane, inside and out. Complex avionics, instruments and fancy interiors or paint jobs can add hundreds of hours to the project. In the real world, the total time to build is largely dependent on the individual builder and his or her habits, efficiency and dedication. It is not uncommon to see two finished RVs at an airshow, comparably equipped, with listed building times that differ by 50-80%.

Even these numbers are suspect. Everyone knows the day they started and the day they flew, but few builders accurately log shop time. RVs are usually finished in 20-30 months elapsed time. The current world record for a Standard Kit (an RV-6 with no pre-punching) is 85 days! Several early RV-3 builders are currently vying for the title of “longest project.”

If the object of the project is to have a flying airplane in the shortest possible time, nothing will help achieve that goal as well as a QuickBuild Kit. QuickBuild Kits are available for the RV-7/7A, RV-8/8A, RV-9/9A, RV-10 and RV-14 (but not for the RV-3, RV-4 or RV-12). About 75% of the riveting is already done on the wings and fuselage when the builder receives the kit. We estimate a QB will save about thirty-five percent of construction time — maybe more.

Other options, such as the Firewall Forward Kit, will also reduce building time by significant amounts.

How can you finish your RV in a reasonable amount of time?

Keep the airplane simple. Extensive avionics, besides being expensive and heavy, take a lot of time to install. Even small changes to the airframe can consume mind-boggling amounts of time. Just a fancy paint job can add months of work.

Work consistently. If you can spend a couple of hours every evening, your airplane will take less time to complete than if you work one long day every weekend. Momentum is important.

Make your shop comfortable year-round. You can’t do good work if you’re miserably cold or hot, and you’ll avoid the shop…not the way to get a project done.

Get your friends and family involved, at least to a point. An extra set of hands can save a lot of time, even if they are just helping move big assemblies or handing you tools.

Make as many decisions ahead of time as you can. Especially when installing systems, you’ll go much faster if you’ve thought it through and bought the parts before you actually need them. If you can reach up, grab what you need and keep building, you’ll be done much faster than if you have to stop and page through catalogs at every decision point…especially if you’re doing the research during prime building time.

Can I Do it?

Literally thousands have.

Building an airplane is a large project that will put you through every imaginable emotion. It is a large project that consumes a lot of time and mental energy. It is unlikely that you will do everything you are doing today and build an airplane, too.

But… when you finish, you will have a unique high-performance airplane that you understand completely. Many builders describe building and flying an RV as one of the most satisfying things they have ever done.

What Will It Cost?

This is one of the more difficult questions to specifically answer since the answer depends significantly on how you want to configure the airplane in the end. While we can give you straight-forward pricing for our kits, it’s pretty much up to you as the builder (within reasonable limits) to determine what sort of engine, propeller and avionics he or she wants to install on the airplane. Those items can significantly impact the overall price of the airplane in the end.

There are a few useful resources we can share, though.

A typical question we get goes something like this: “I’d like more information on building one of these kit planes. What tools are needed, what about hole drilling, how many celcos are needed and what’s the average cost of building this project? I’m looking at the RV-7A.”

Overall, costs can vary significantly depending on configuration, engine and prop choices, avionics choices, etc. We will typically share a few helpful links with someone researching RV building costs:

Building an RV – Overview:

https://www.vansaircraft.com/building-an-rv/

Tool info, including links to recommended tools and supplier info:

https://www.vansaircraft.com/building-an-rv/tools/

Our RV kit prices and availability lead times are always maintained at this link:

https://www.vansaircraft.com/order-a-kit/kit-prices-and-lead-times/

From an engine/propeller/avionics perspective, the options are quite varied and the decisions in this area are personal and customized to the individual. You can buy used or new, and you’ll choose the brand and style of prop, engine configuration, whether you want VFR or IFR avionics, glass panel or round dials, etc. A used mid-time engine and propeller plus basic avionics will run quite a builder a bit less than an all-new engine, propeller and glass instrument panel with IFR avionics. So, you can make your choices based on your own priorities and budget – and end up with a great airplane in any case.

We have new engine and propeller prices available on our order forms, which are accessible at this page:

https://www.vansaircraft.com/order-a-kit/

Avionics – with the exception of the RV-12 – are not purchased from Van’s. There are a number of excellent third-party vendors who can provide what you need to build and wire your own panel. There are even vendors who can fabricate a custom panel and build it all for you with a finished wiring harnesses, ready to quickly install and plug in.

Hopefully that helps answer some of the most common questions!