Nose Gear Shimmy

My nose gear shimmies… What can I do about it?

A builder can reduce or eliminate nose/main wheel shimmy by paying close attention to the factors that can aggravate it. Keep in mind that almost all RV models will exhibit limited nose/main gear/wheel shimmy during certain taxi conditions, even the nose gear on Van’s demonstrators “shimmy” on occasion.

The following is a list of suggestions that may help minimize nose gear vibration.

- The NOSE wheel tire pressure should be between 25-35psi. Less is better as it increases the tire drag, which will help damp any shimmy. The MAIN tires should be inflated to between 25 and 35 PSI and be equally pressurized. The balance of the wheel/ tire assemblies is important as well – all of them!

- It is possible that NOSE wheel shimmy is excited by MAIN gear/wheel shimmy. If so, the wood dampener strips suggested in the construction manual for the main gear might be necessary. Further, uneven tire wear (found on any tire) can also contribute to wheel shimmy.

- The torque on the nose wheel axle bolt may need adjusting. The axle bolt should be torqued to 7-10 pounds per the construction manual.

- Pilot technique is extremely important. Keep weight off the nose wheel as much as possible by holding the stick aft (up-elevator). If you insist on three pointing the airplane at 70 MPH and jumping on the brakes (which, frankly, is horrible piloting technique), shimmy is almost assured.

- On higher time airframes, check the engine mount and gear leg for any cracks or play. It is possible that the gear leg attach bolt at the top of the leg is loose allowing movement of the leg in the mount socket.

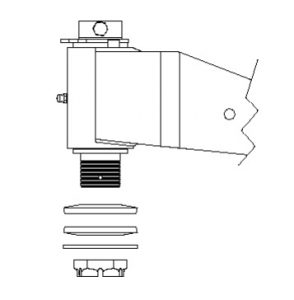

- Finally, are the nose fork disc springs clean and mounted correctly (see below)? Also, make sure the breakout force is at the recommended 22 pounds (SEE DWG C-1).