Wing Wiring: Routing Wires in the Wings

There are a number of installations that require routing of wires and tubes in the wing. These may include nav lights, strobe lights, landing lights, heated pitot, nav antenna, autopilot, AOA and maybe a stall warning device. Listed here, in no particular preference, are some ways to run wires and tubing through the wing ribs.

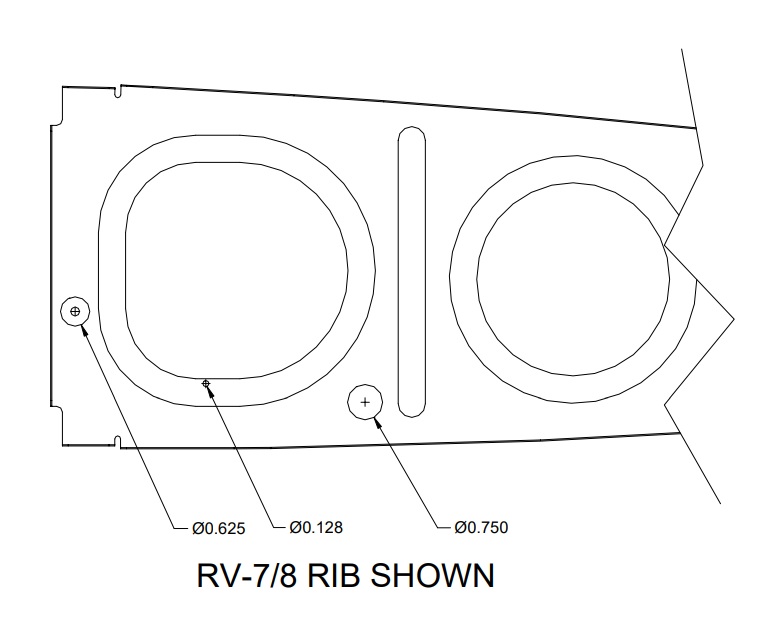

1. The tooling holes in the ribs may be drilled to a maximum of 5/8” and plastic Bushings SB625-7 installed. These bushings have a 7/16” inside diameter and should be adequate for most needs. Of course, smaller bushings can also be used.

2. An additional hole may be drilled in the lower 1/3 of the rib between the large lightening hole and the next one aft. This hole may be up to 3/4” diameter to accommodate our wiring conduit (DUCT NT 5/8-50) or Bushing SB750-10 (5/8” I.D.). The conduit is light and flexible. It’s .810 “ outside diameter means that when snapped into place, the corrugations hold it from slipping out. If using the conduit, a dab of fuel tank sealant or RTV should be put on the conduit at each rib to prevent the conduit from being cut through over time from vibrations.

3. You can drill a small hole, #30 will do, near the edge of each lightening hole in the rib and use a cable tie to tie either wire or conduit in place. Be sure to protect the wire from chafing on the lightening holes. Hint: To get a pull string through the conduit, tie the string to a cotton ball and blow it through with an air gun or suck it with a vacuum. In all instances, make sure that there is no interference with the aileron bellcrank or control rods.